Three-axis Nanopositioning Stage For Vacuum

Dynamic Structures And Materials, LLC

Three-axis Nanopositioning Stage For Vacuum by Dynamic Structures And Materials, LLC

Related Technologies:

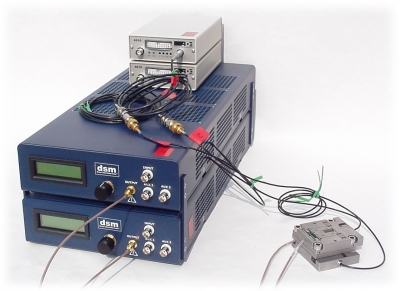

When one of DSM's customers required a custom three-axis positioning system, DSM leveraged the flexure-based design of its flextensional piezo actuators to create independent X, Y, and Z stages. The resulting X and Y stages each provide 200 microns of travel, and the Z axis has a stroke of 500 microns. The original stage assembly was designed for vacuum compatibility and was provided with benchtop models of DSM's VF linear piezo amplifier. The basic design of the stage systems is scalable to smaller/larger displacement capabilities.

As a follow-on deliverable to the original, open-loop XYZ system above, DSM's customer requested closed-loop capability for the X and Y axes. DSM incorporated capacitive probes and used SA-100 linear servo amplifiers to provide stand-alone servo control. A 24-bit analog input accepts the position target signal, and digital I/O provides flags for "in-range" and data acquisition triggers.

Go Back to Cable Test Gantry Systems

About Dynamic Structures And Materials, LLC

Dynamic Structures and Materials, LLC (DSM) specializes in electrical-mechanical design and prototyping services for challenging devices, machines, and systems. By partnering with industrial designers, engineers, and scientists, DSMís varied expertise has enabled new and unique product development for industrial and consumer applications. DSM has extensive experience in motion control applications including micropositioning and nanopositioning system design using flexure-guided motion components. Specialty Motion System Competencies -------------------------------------------------- * Linear and rotary actuation systems for scanning applications, valves, and micro / nanopositioning equipment design * Flexure-guided mechanism designs for smooth motion * Piezoelectric and shape memory alloy materials Controls Software and Sensors -------------------------------------------------- * National Instruments LabVIEW VIs (CLAD certification), serial and USB communications, DLLs * HMI development * C, C++.net, VB.net, ASSEMBLY * Digital and analog sensor integration, data acquisition * Linear and non-linear control systems, including PID Electrical Circuit Design Capabilities -------------------------------------------------- * 50+ combined years of product design experience * Circuits for analog and power applications * Microcontroller and DSP implementations * Ultrasonic switching drivers for piezoelectric devices * Embedded systems software development Solid Modeling, Mechanical Design, FEA -------------------------------------------------- * 3D, 2D CAD * FEA-optimization of mechanisms and structures * Static, dynamic, modal, and transient analysis Precision Machine Design and Automation -------------------------------------------------- * Robotics, machine vision, laser scanning * Air bearing systems, harmonic drives, linear motors