Controlled Shaker System For The International Space Station

Dynamic Structures And Materials, LLC

Controlled Shaker System For The International Space Station by Dynamic Structures And Materials, LLC

Related Technologies:

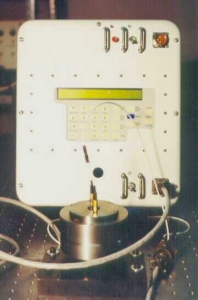

DSM was contracted by the Boeing Corporation to develop a complete proof-mass shaker system. The system consisted of a low profile, high force shaker, an arbitrary waveform generator, and an efficient amplifier for use in testing the limits of the current active and passive vibration suppression systems aboard the International Space Station (ISS). The technology within the shaker was developed through a BMDO-funded SBIR program for piezoelectric vibration suppression actuators.

Within three months DSM designed, developed, produced and delivered a demonstration system for Boeing to test. One month later, DSM was able to deliver a MIL-I flight qualified unit. The shaker system was subsequently delivered to the ISS by the Space Shuttle Endeavor.

About Dynamic Structures And Materials, LLC

Dynamic Structures and Materials, LLC (DSM) specializes in electrical-mechanical design and prototyping services for challenging devices, machines, and systems. By partnering with industrial designers, engineers, and scientists, DSMís varied expertise has enabled new and unique product development for industrial and consumer applications. DSM has extensive experience in motion control applications including micropositioning and nanopositioning system design using flexure-guided motion components. Specialty Motion System Competencies -------------------------------------------------- * Linear and rotary actuation systems for scanning applications, valves, and micro / nanopositioning equipment design * Flexure-guided mechanism designs for smooth motion * Piezoelectric and shape memory alloy materials Controls Software and Sensors -------------------------------------------------- * National Instruments LabVIEW VIs (CLAD certification), serial and USB communications, DLLs * HMI development * C, C++.net, VB.net, ASSEMBLY * Digital and analog sensor integration, data acquisition * Linear and non-linear control systems, including PID Electrical Circuit Design Capabilities -------------------------------------------------- * 50+ combined years of product design experience * Circuits for analog and power applications * Microcontroller and DSP implementations * Ultrasonic switching drivers for piezoelectric devices * Embedded systems software development Solid Modeling, Mechanical Design, FEA -------------------------------------------------- * 3D, 2D CAD * FEA-optimization of mechanisms and structures * Static, dynamic, modal, and transient analysis Precision Machine Design and Automation -------------------------------------------------- * Robotics, machine vision, laser scanning * Air bearing systems, harmonic drives, linear motors