Gun Drill Controls Upgrade For Old Eldorado Gun Drills by Turbocraft, Inc.

Related Technologies:

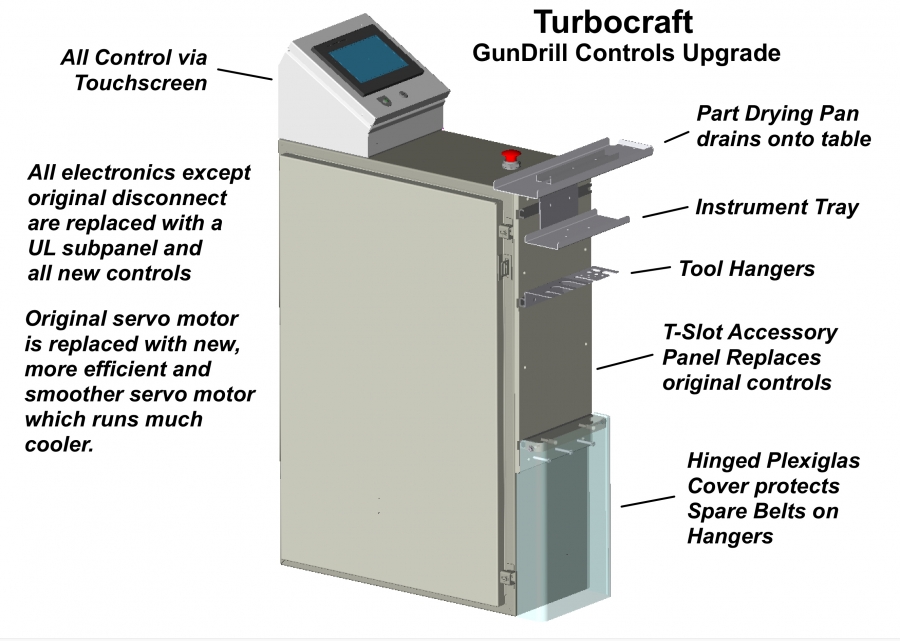

Replacement for the hard-to-find servo motor and controls on the old Eldorado Tool Co. Gun Drills.

All controls are replaced with a modern easy to use touchscreen.

Old servo motor and drive are replaced with new servo motor and programmable controller (PLC).

All previous options are included (except skip jog) assuming you have the original hardware for it.

Each part setup includes Feed Rate, Start position, End position, No of parts setpoint, Tool Change setpoint, Part Name, Setup Notes, timer setup (ET per part, or for whole run of parts).

Each part setup can be saved as a "recipe" and recalled later - up to 496 different setups.

Servo motor has 15% more torque than the original, and runs much smoother and cooler - resulting in up to 50% less need for drill sharpening or replacement.

Touchscreen displays spindle motor and servo motor torque, and tracks maximums reached, which can be reset at any time.

Onscreen replacement pushbuttons for starting and stopping the coolant oil pump.

Tracking of total number of parts run, and total hours for Spindle Motor.

Numerous alarms screens.

Many more features.

All electronics in the panel are replaced (except main disconnect unless necessary) with a self-contained UL labeled sub panel.

Original controls are removed and holes covered with a T-slot Accessory panel. Optional accessories include Part Doing Tray that drains onto table, Instrument Tray, Tool Hanger, and Belt Hanger and hinged cover.

Application range is 1 hp to 7 hp Spindle Motors.

Most of these old gun drills have great iron, and just need new controls. This is the solution!

Go Back to Vision System Industrial Printing Machines

About Turbocraft, Inc.

Turbocraft is an engineering services company that has expertise in Factory Automation, Machine Design, Manufacturing Engineering, Process Control, Systems Integration, Instrumentation and Controls, PLC Programming, Operator Interface Design, Specialty Machinery, Tool Design, and CAD services. Turbocraft can re-design existing parts to improve manufacturability. We can design the manufacturing equipment to make the part/s. We can take an existing manufacturing process and automate it. We can design an automation/process control system, and integrate the machine, sensor, controls, and operator interface into your factory environment. We can re-program your existing PLC’s to incorporate additional manufacturing steps, or design and test a new PLC program. We can engineer your manufacturing tooling and shop aids. We can prototype your new part/s in 3D CAD and provide fully rendered views so you see what it looks like before it is built. We also have experience in guiding ideas through the patent process. PLC manufacturers that we have experience with are Opto 22, Allen Bradley, Omron, IDEC, Automation Direct, & Beckhoff.