Sapient Automation News and Press Releases

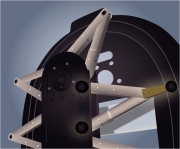

Hatfield, PA (July 27th, 2012) - Self-lubricating wheels on the scissor arm assemblies of Sapient Automation Avengerô Vertical Carousels helps extend its operational life in storage and retrieval applications while reducing maintenance costs. Generally, Vertical Carousels require periodic lubrication as part of a preventative maintenance routine to assure reliable operation. Self-lubricating scissor arm wheels reduce maintenance downtime and extend service life. This is particularly valuable during busy times when the unit is accessed more than normal and if the unit is overloaded. Likewise, the new wheel is valuable in providing whisper quiet run time especially when compared to other metal, plastic and non petro-based materials. The self-lubricating wheel is a new component in the Avenger Vertical Carouselís scissor arm design to provide even higher levels of reliability. Instead of using a single scissor arm d...

Hatfield, PA (June 5th, 2012) - Expert at Implementing Automated Systems Focused On Reducing Labor, Floor Space, Increasing Ergonomics for Order Picking, Split Case and Item Material Handling, Manufacturing, Spare Parts Handling, Health Care, Tool and Die Retail and Institutions Applications, Tim Harrison Joins Sapient Automation Tim Harrison of Noblesville, Indiana, has been named Midwest Sales Director by Sapient Automation, manufacturers of automated storage and retrieval systems, Hatfield, Pennsylvania. Before joining Sapient Automation, Harrison worked as a senior account executive for Pick and Store Systems, Indianapolis, Indiana. Pick and Store Systems is one of Kardex Remstarís leading dealerships. Harrison implemented many Vertical Lift Module (VLM), Vertical Carousel and Horizontal Carousel systems in leading organizations such as Caterpillar Inc., Rolls Royce, Cook Medical Inc. and many more. Workin...

Hatfield, PA (June 5th, 2012) - New ViperTilt tray system in Viper VLM from Sapient Automation improves ASRS Vertical Lift Module Ė VLM - ergonomics, productivity, accuracy and space savings in order fulfillment storage and retrieval material handling operations vital in JIT inventory management systems The new ViperTiltô tray delivery system available on the Viperô Vertical Lift Module (VLM) from Sapient Automation provides ergonomic order picking of parts and items for increased levels of ergonomics, accuracy and productivity in automated storage and retrieval systems operations. The Viper VLM delivers a tray to the pick window and then the ViperTilt automatically lifts the rear of the tray up towards the operator from a 25 to 45 degree angle depending on the type of items being stored. With an aging and diverse work force being the norm these days, the vertical storage system tilt tray design on the Viper Ve...

Hatfield, PA (April 2nd, 2012) - The new point of use Mini-Avengerô Vertical Carousel Cart system provides ergonomic high density secure storage for work areas and cells. This new system saves up to 65 percent of wasted floor space while increasing operator productivity by up to 2/3 by eliminating wasted walking and searching time. The Mini-Avenger Vertical Carousel Cart is portable and designed to move through facilities, standard halls and doorways to the point of use. The unit comes with roller ball bearing caster wheels which allow minimal effort to move quickly and easily. Units can be dedicated to a work station or area or rotated for replenishment, kitting, consolidation, buffer or pick and pass applications. Inventory and items are stored in the mini vertical carousel on carriers or shelves which rotate on an oval track vertically and delivered to an ergonomically located work counter. Every shelf can be ...

Hatfield, PA (February 17th, 2012) - Sapient Automation has released their new high density, automated storage and retrieval system literature on the Avengerô Vertical Carousel. The carousel system literature provides key information on how organizations reduce labor, floor space requirements and inventory while providing a fast return on investment (ROI). The Avenger Vertical Carousel literature details the key elements designed to provide organizations unsurpassed levels of the carouselís reliability and longevity. Historically Vertical Carousel Automated Storage and Retrieval Systems (AS/RS) use one location on the chain to support two carriers. The Avenger vertical carousel's arms mount to the chain in their own exclusive position. If there is any pressure or stress, it is not passed through to the other arms. This helps eliminate the potential for any cascading effect and unit failure. In other designs, if ther...

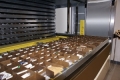

Hatfield, PA (February 17th, 2012) - The new Viper Vertical Lift Module (VLM) automatic tray height scanning system and tray design can provide more than 50% more storage density while allowing organizations to lower their automated storage and retrieval systems acquisition cost. The new Viper Vertical Lift Module automatic tray height scanning system determines each trays exact storage height requirement down to a one inch increment automatically every time a tray is retrieved. The VLMs control system determines the optimum storage position in the unit based on optimizing space and retrieval time. The new tray design uses a number of enhancements to provide increased levels of storage capacity. The Viper VLM tray now uses thinner side walls, flat bottoms and no dividers or support cross members in the open storage area. Likewise, the trays are available in two, three and four meter widths at very economical levels ...