New Avenger Vertical Carousel Literature Details Automated Storage And Retrieval Benefits Automated Storage And Retrieval Systems Asrs Improves Small Parts Order Picking, Order Fulfillment Efficiency

New Avenger Vertical Carousel Literature Details Automated Storage And Retrieval Benefits Automated Storage And Retrieval Systems Asrs Improves Small Parts Order Picking, Order Fulfillment Efficiency

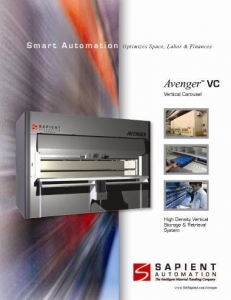

Sapient Automation has released their new high density, automated storage and retrieval system literature on the Avengerô Vertical Carousel. The carousel system literature provides key information on how organizations reduce labor, floor space requirements and inventory while providing a fast return on investment (ROI).

The Avenger Vertical Carousel literature details the key elements designed to provide organizations unsurpassed levels of the carouselís reliability and longevity.

Historically Vertical Carousel Automated Storage and Retrieval Systems (AS/RS) use one location on the chain to support two carriers. The Avenger vertical carousel's arms mount to the chain in their own exclusive position. If there is any pressure or stress, it is not passed through to the other arms. This helps eliminate the potential for any cascading effect and unit failure. In other designs, if there is any disturbance or pressure on the arms it will typically bend, twist and torque and potentially destroy multiple arms in a cascading effect.

The literature details how the Avenger Vertical Carouselís flexibility to configure the carrier/shelf helps meet specific inventory and application requirements. For example, roll out drawers, totes or containers, adjustable shelf heights and partitions which can maximize storage space and productivity. A wide range of integrated Sharkô inventory management software and Pick to Light systems are available to improve efficiencies.

From stand alone work stations to integrated work zones, the Avenger Vertical Carousel from Sapient Automation can help organizations implement their Lean Manufacturing and Distribution programs, Six Sigma, and Sustainability initiatives.

Security and restricted access for parts, inventory and material is easily accomplished with the Avenger Vertical Carousel. Incremental security features are available to meet almost every facility and department needs. From locking bi-parting doors to keep unauthorized users from accessing the unit, to individual user password controlled access to shelves with full user logs are available.

The reliability and up time of the Avenger Vertical Carousel is legendary with some models carrying up to a 10 year parts and service manufacturer warranty! This unprecedented warranty underscores the design and manufacturing superiority of the Avenger carousel. For years organizations around the world have been able to take advantage of the MTBF (Mean Time Between Failure) rates that rival and surpass many household appliances.

With a push of a button, click of a mouse or scan of a bar code, the Avenger Vertical Carousel rotates via the shortest path to deliver items to the operator. An array of pick to light technologies ranging from simple light indicators to full message Transaction Indicator Lights (TIC) strips aid productivity and throughput requirements.

Sapient Automation is a leading provider of automated storage and retrieval systems that reduce leading organizations requirements for labor, floor space and inventory while dramatically increasing productivity and operational efficiencies with often a nine to 18 month Return on Investments (ROI). Industries served include: manufacturing, distribution, warehouses, healthcare, institutions, retail and wholesale organizations. The Sapient Automation technologies include the Viper Vertical Lift Module (VLM), Avenger Vertical Carousel, Hornet Horizontal Carousel, Shark Inventory Management Software, PickaMed Carousels and Spit Fire Pick Carts and pick to light systems.

For information about the Avenger Vertical Carousel call 888-451-9711 or visit the Sapient Automation web site at www.GetSapient.com