Sensor And Harness Verification by Comptek, Inc.

Related Technologies:

New Federal Emissions standards are causing many automotive companies to redesign their powertrain packages to provide better fuel economy and fewer pollutants. As a result, many powertrain subsystems and devices are becoming more sophisticated. This was the case with one manufacturer of exhaust systems who was chartered with the requirement to test and verify electronic components that were now required as a part of the exhaust assembly.

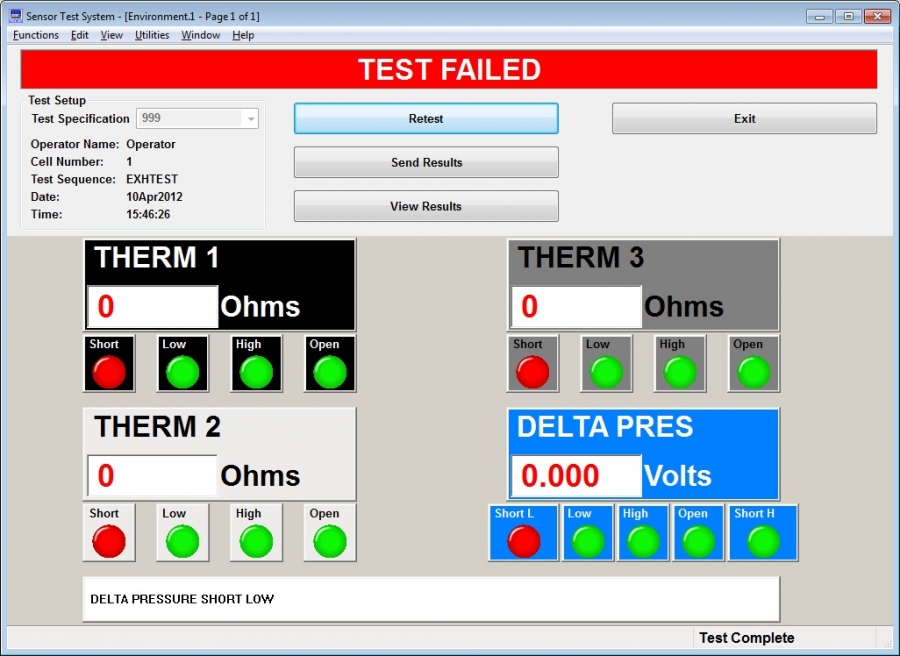

The manufacturer was required to verify the functionality of temperature probes and pressure transducers that were mounted to the exhaust assembly and connected by a common wire harness. A pressurized leak test was also performed on the part.

Comptek used itís computer based controls expertise to deliver a simple and cost effective system that would plug into the harness connector and test the harness and electronic devices for continuity and functionality. The computer based system was simple and easy to use for plant floor assembly personnel. The system was configured to run functional tests on various exhaust assemblies and save the performance results to a database. Engineers could query the database to determine failure trends in their assembly process.

Go Back to Traceability Packaging Machines

About Comptek, Inc.

COMPTEK is a supplier of computer based systems and engineering services for industrial automation applications. Our manufacturing assembly and test applications include engine, generator and harness test systems; assembly line monitoring and in-process verification stations; ECM module programming and CAN interface software; data acquisition and instrumentation design & build; leak test monitoring systems; fuel conditioning systems; test cell data servers; operator consoles; assembly line set and printer stations; part verification bins; and computer and instrumentation enclosures. Capabilities include hardware and software simultaneous engineering, design, hardware assembly and build, software programming, commissioning, on-site support, documentation & training. Since 1983 COMPTEK has addressed the computer automation needs of the industrial marketplace. We specialize in providing products and services for computer based industrial assembly, test and control systems. COMPTEK integrates hardware and software capabilities into a cohesive efficient computer system. We provide plant floor systems for: Production monitoring and control; functional product tests; data retention and analysis; operator and management real-time displays and reports. Our experience on computers encompasses a wide variety of applications using various custom designs. In the ever changing industry of computer hardware and software, COMPTEK designs, provides and supports systems using "field proven", state of the art components. COMPTEK systems are designed to be independent of the computer processor, operating system and data acquisition hardware. This enables the application to be easily ported to new products and concepts as they become available in the industry. The following systems illustrate our applications experience: * Engineering, quality audit and production testing of diesel engines * Production testing of automotive transmissions * Cold and Hot testing of gasoline engines * In process verification of components during assembly * Management and Information systems for assembly and test operations * Electronic Control Module (ECM) interface, communications and programming * Central Data Systems for networking cell controllers