Fastpic Software Makes A Vlm Even Smarter

FastPic5 inventory management software saves time, increases efficiencies and maximizes storage density by managing height and weight restrictions. While the unit can control these features, FastPic5 inventory management software is designed to proactively supervise this function resulting in an even smarter Shuttle Vertical Lift Module (VLM).

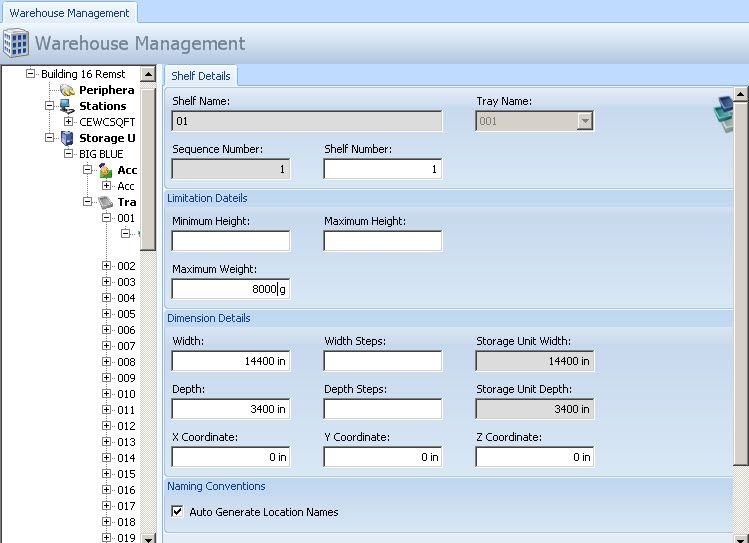

Using the height restriction feature in FastPic5, each tray can be preset with a maximum height for stored goods. To maximize storage density within a VLM most efficiently, each tray should contain parts of the same approximate height. Using FastPic5 prevents the operator from increasing the overall tray height, restricting the operator from creating wasted cube. For example, if a tray has been loaded with parts all 8” high, the tray could be set to store goods at a height of 8”, and 8” only. This will prevent the operator from loading that 8” specified tray with a 10” part, and creating 2” of wasted space.

The VLM manages this function by scanning the height of the tray as the extractor brings the tray back into the machine and stores it. To prevent losing space, if a restricted tray height is exceeded the VLM will deliver the tray back to the access opening and identify to the operator that the restricted height has been exceeded. Operators can set the height restriction of each tray individually.

Using the weight restriction feature, FastPic5 can also manage the weight held on each tray, as well as the total unit weight. Using FastPic5 each tray weight capacity is preset as light, medium or heavy. FastPic5 then directs the operator to put or store a part in an assigned location where there is adequate weight capacity, never exceeding the tray or unit weight. Managing tray capacity is important to keep functionality of the machine running at full speed. Using FastPic5 to manage storage locations and weight capacities ensures the VLM will be loaded efficiently, preventing wasted time from manually managing the weight capacity.

Space is always a factor when looking to improve any operation. While the height and weight of stored parts can be managed by the VLM, FastPic5 increases efficiencies making operations smarter. FastPic5 proactively manages the height and weight restrictions in a VLM- saving time and effort, while increasing efficiency and productivity.

Kardex Remstar, LLC, a company of the Kardex Group is a leading provider of automated storage and retrieval systems for manufacturing, distribution, warehousing, offices and institutions. For information about our dynamic storage solutions, call 800-639-5805, visit www.KardexRemstar.com.