Batch Put Away Makes Replenishment A Whole Lot Easier

Batch Put Away Makes Replenishment A Whole Lot Easier

Replenishing stock just got a whole lot easier. FastPic5 inventory management software is now available with a batch put away function. Instead of replenishing inventory one part at a time, FastPic5 allows multiple parts to be replenished at one time. This improves not only the speed of the replenishment process but increases productivity and accuracy.

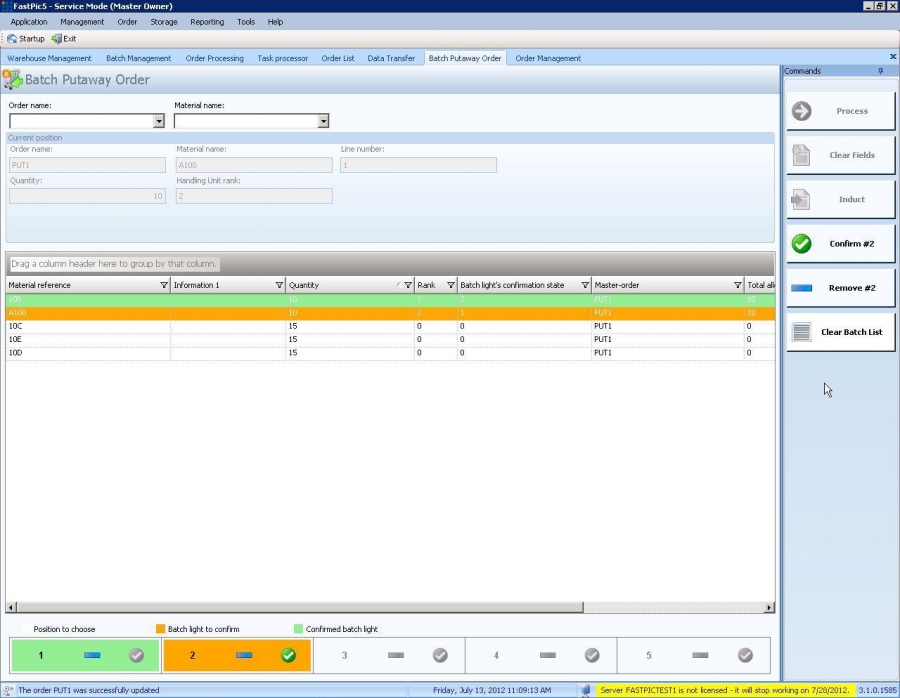

Batch put away is the process of putting away multiple parts simultaneously. Selected restock parts are batched and are put away concurrently. Each replenishment item is treated as an order and is assigned an individual tote before the process begins. The machine will move to the first put away location with pick to light technology indicating the quantity and location of the items to be replenished. The operator then presses a confirmation button indicating the part has been replenished.

Using FastPic5 to manage replenishment can increase the operators speed. Eliminating the need to walk through aisles of shelving or drawers to put away individual items one at a time, the operator uses the time previously wasted to put more goods away. With the touch of a button, the machine moves to bring the put away location directly to the operator at an ergonomic height. The process simply becomes a batch put away process from a stationary zone.

When using dynamic storage systems, FastPic5 organizes and manages the put away sequence to increase the overall productivity of batch put away. In single put operations, an operator may visit the same tray or carrier multiple times to access different put locations, causing dwell time as the machine retrieves the tray or carrier multiple times. FastPic5 optimizes the put away orders so multiple locations on the same tray or carrier are processed in sequence, only requiring the machine to access the tray or carrier one time.

Put light technology navigates the operator throughout the entire batch put away process. Pick lights on the batch station direct the operator which items to pick and put lights on the machine indicate where the operator should put the items, including how many to store in that location. This increases the accuracy of replenishment, ensuring the correct quantity of goods are being put in the right place. This leads to fewer part shortages or missing parts during the picking process.

Kardex Remstar, LLC, a company of the Kardex Group is a leading provider of automated storage and retrieval systems for manufacturing, distribution, warehousing, offices and institutions. For information about our dynamic storage solutions, call 800-639-5805, visit www.KardexRemstar.com.