Adaptacell Debut

February 6, 2005

FOR IMMEDIATE RELEASE

For information contact: Joanne McFadden

Special Projects Coordinator

585-647-2230

joanne@ramtc.com

Manufacturing leader announces a practical, results-oriented approach to lean manufacturing

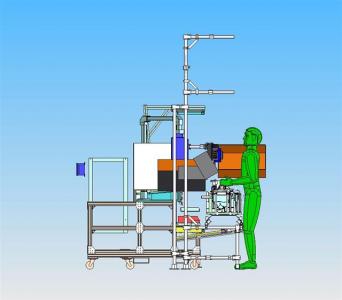

Rogers Associates, a manufacturer of quality machines and turnkey automated systems, unveiled a flexible assembly and test platform recently well suited for lean manufacturing projects. Designed for use in a multitude of industries, the AdaptaCell® is an ideal solution for products with short life cycles and where design changes are likely.

“These applications are often difficult to justify dedicated automation costs, “ explains Jeff McFadden, president and CEO of the Rochester, NY-based machine tool company. “ The AdaptaCell® is easily re-configurable allowing design changes and/or new products to be incorporated into the system.”

The modular system, said Mr. McFadden, can be configured in a variety of layouts and product transfer schemes. It is configurable to be used with products weighing less than 100 pounds and occupying a work envelope of 2 by 2 by 4 feet or less. While the AdaptaCell® allows for a myriad of designs, there are three standardized beginning configurations: a u-shaped configuration, an in-line configuration with automated pallet return, and a rectangular layout with manual or automated pallet transfer. Typical applications combine manual and automated process. ‘

A typical station can also be configured with an overhead support structure used to secure task lighting and tool balancers. A wide variety of equipment including leak testers, functional testers, and welding equipment is easily incorporated into the base system. As product volumes ramp up, additional automation elements can be added to the system. This feature allows the AdaptaCell® to grow along with demand. As the system is created from a standard platform of components, lead times are extremely short.